The fixed overheads for the factory amount to ₹50,000 per month, and the company produces 5,000 chairs in a month. The variable overheads (for utilities and factory supplies) amount to ₹5,000 in total. Using absorption costing, the company would allocate ₹10 per chair for fixed overheads (50,000 ÷ 5,000 chairs) and ₹1 per chair for variable overheads (5,000 ÷ 5,000 chairs). The company can use this total cost to set the selling price and assess profitability. Absorption costing is an accounting method employed for allocating all direct and indirect production costs to individual products. This methodology is essential because it encompasses all costs incurred recording transactions in the manufacturing process, thereby enabling manufacturers to set product prices that adequately cover the full scope of production expenses.

- Even businesses with comprehensive manufacturing and managerial accounting know-how need a cohesive solution to accurately implement absorption costing principles.

- Absorption costing is a widely used accounting method that helps businesses determine the full cost of producing a product by considering both fixed and variable costs.

- However, absorption costing is essential for financial reporting, as it aligns expenses with revenue recognition.

- Your production costs by the absorption method are $100 per blanket, or a total of $1 million.

- Choose a solution like NetSuite that accommodates both, giving you the best of both worlds.

- Rules like the Uniform Capitalization (UNICAP) rules specify how to treat these costs.

- You can calculate a cost per unit by taking the total product costs / total units PRODUCED.

Add up all manufacturing costs

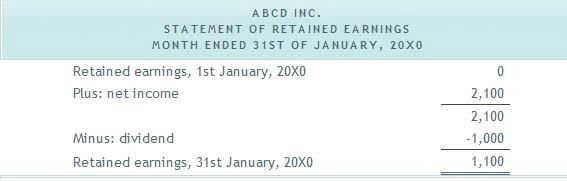

When we prepare the income statement, we will use the multi-step income statement format. Next, we can use the product cost per unit to create the absorption income statement. We will use the UNITS SOLD on the income statement (and not units produced) to determine sales, cost of goods sold and any other variable period costs. Absorption costing allocates all manufacturing costs to products, thereby ensuring that each unit carries a proportionate share of fixed overhead expenses. For instance, if the direct costs (materials and labor) for a chair are ₹500, and the allocated overhead costs (fixed and variable) are ₹100, the total cost of producing that chair would be ₹600. By shifting some portion of production costs to the balance sheet rather than on the income statement when they are incurred, absorption costing can result in temporarily inflated net income.

Absorption costing: Definition, formula, and how it works

In simple terms, you combine every manufacturing expense incurred, from direct materials and labor to variable overhead and fixed overhead, and then spread that total cost evenly across all the units made in that period. Absorption costing generally results in a somewhat higher cost of goods sold and lower gross profit than variable costing, while potentially boosting net income. This is because SG&A costs are lower, a result of shifting fixed manufacturing overhead into production costs.

Allocate costs to unsold inventory

- Absorption costing includes all manufacturing costs in the value of your inventory.

- Using an inappropriate base can distort individual product costs and profitability.

- Ultimately, getting absorption costing right leads to more dependable information for running your business.

- In such scenarios, absorption costing serves as the go-to accounting methodology for calculating the complete cost of producing each unit of a product.

- These costs are straightforward because they can be directly linked to the production process.

- Ascertaining these costs gives a business a basis for setting a profitable price for a product.

Now, let’s explore how absorption costing is actually calculated in a more detailed manner. The process involves several steps, as both direct and indirect costs need to be assigned to the products in a way that reflects their consumption of resources. Although manufacturing companies must use absorption costing when preparing external reports such as regulatory filings, they typically use other cost accounting methods, such as variable costing, for internal analysis. Absorption costing adheres to GAAP, which requires matching product costs to product sales in the same period. It also requires recording the costs of unsold goods as inventory, an asset on the balance sheet.

Demystifying Absorption Costing: A Comprehensive Guide to its Application and Nuances

- While this task may seem straightforward for companies specializing in a single or limited range of products, it becomes increasingly complex for firms with a diverse product portfolio.

- You can generate the standard financial statements you need, plus custom reports that clearly reflect your costs based on absorption costing rules.

- Absorption costing has several advantages that make it an attractive method for costing products, especially in traditional manufacturing environments.

- Absorption costing can skew a company’s profit level due to the fact that all fixed costs are not subtracted from revenue unless the products are sold.

- Absorption costing incorporates all these costs into the inventory valuation, although it excludes other business expenditures like administrative and sales expenses.

- Absorption costing is a managerial accounting method for capturing all the costs related to manufacturing a product.

Using absorption costing means the inventory value shown on the balance sheet reflects the complete manufacturing cost invested in those goods. Finally, to find the COGS, multiply the absorption cost per unit by the number of motors sold during the month. We’ll use a fictional motor company, Bookkeeping vs. Accounting “Precision Motors Ltd.,” for the month of July. These costs represent the essential infrastructure, equipment, and core personnel required to keep the factory operational, regardless of the specific number of units produced day-to-day. Absorption costing is a managerial accounting method for capturing all the costs related to manufacturing a product.

That cost only moves from the balance sheet to the income statement when your business actually sells the product. The total Cost of Goods Sold (COGS) for the month is then $6.50 multiplied by the 8,000 coats sold, resulting in $52,000. The value absorption costing formula of the remaining inventory is $6.50 multiplied by the 2,000 unsold coats, which sums up to $13,000. The total Cost of Goods Sold (COGS) for the quarter is calculated as $3.50 per tee multiplied by the 12,000 tees sold, equalling $42,000. The value of the remaining inventory is $3.50 per tee times 3,000, which totals $10,500. Where this seemingly straightforward formula gains complexity is at the sub-component level—that is, in the granular calculation of each variable in the numerator.

- Handling absorption costing means you need to accurately track all your manufacturing costs and allocate overhead correctly.

- When your product costs accurately reflect all manufacturing expenses, you have a stronger basis for planning.

- Though both products share a common material, the amount of fabric and labor required for each differs significantly.

- This approach provides clearer insights into incremental production costs and profitability per unit but does not comply with GAAP for external reporting.

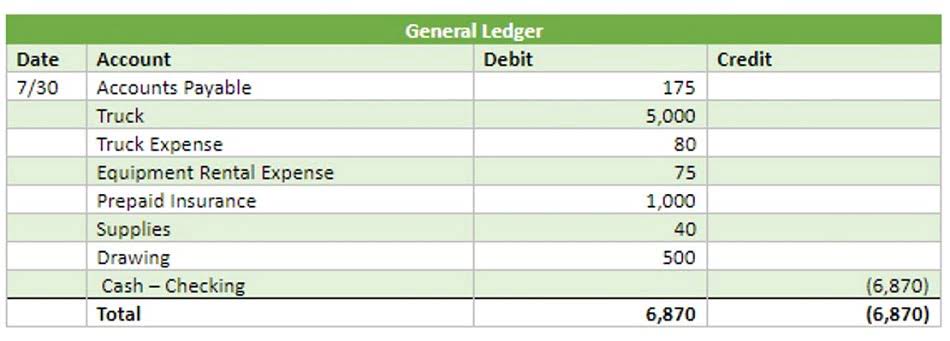

Choose a solution like NetSuite that accommodates both, giving you the best of both worlds. With NetSuite’s financial management software, you can not only generate GAAP and IRS-compliant financial statements using absorption costing, but also automatically employ variable costing for internal business analyses. Importantly, under GAAP guidelines, unsold products are reported on the balance sheet as inventory and are not expensed until they are sold. Given the all-encompassing nature of absorption costing, this often leads to a higher per-unit Cost of Goods Sold (COGS) compared to other costing methodologies. Optimizing the efficacy of absorption costing often entails a meticulous setup of the chart of accounts and, subsequently, the general ledger.